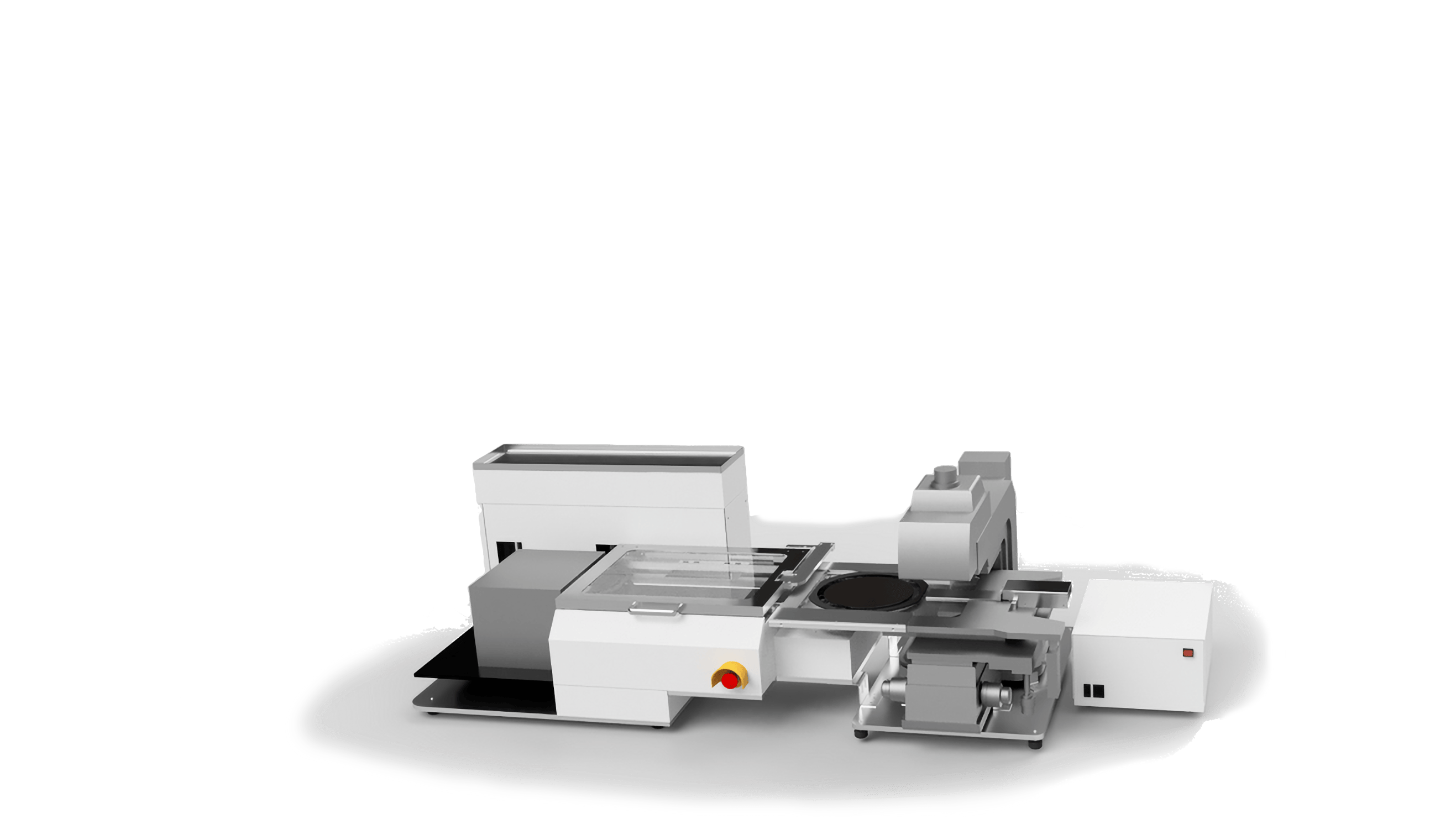

The In-line Assembly Inspection System delivers state-of-the-art quality control for semiconductor assembly processes. Combining high-speed imaging technology with advanced AI-powered analysis, this system provides continuous, real-time inspection without impacting production flow. Designed for modern semiconductor manufacturing lines, it ensures consistent quality while maintaining optimal production speeds.

Key Features

Real-Time Inspection Technology

Our advanced imaging system enables continuous inspection at full production speeds. Multi-angle cameras and specialized lighting provide comprehensive component visualization while sophisticated algorithms ensure accurate defect detection during high-speed operation.

AI-Powered Defect Detection

Advanced machine learning algorithms analyze assembly quality in real-time, identifying subtle defects and variations. The system's neural networks continuously improve detection accuracy through production learning and pattern recognition.

Intelligent Process Monitoring

Comprehensive monitoring system tracks assembly parameters and quality metrics throughout production. Real-time analysis enables immediate process adjustments to maintain optimal assembly quality and prevent defect occurrence.

Benefits

Continuous Quality Assurance

Real-time inspection ensures immediate detection of assembly issues, preventing defect propagation. The system's advanced monitoring capabilities maintain consistent quality standards throughout extended production runs.

Maximized Production Efficiency

Seamless integration with assembly lines eliminates production bottlenecks. The system's high-speed inspection capabilities match production rates while maintaining comprehensive quality control.

Advanced Process Control

Intelligent feedback systems provide immediate process optimization data. Comprehensive quality metrics enable proactive adjustments to maintain optimal assembly parameters and prevent quality deviations.

Applications

Semiconductor Assembly

Specialized capabilities for various assembly processes including die attach, wire bonding, and encapsulation inspection. Supports high-volume production with continuous quality monitoring.

Advanced Packaging

Enhanced inspection capabilities for advanced packaging technologies including flip-chip, system-in-package, and multi-chip modules. Adapts to complex assembly requirements.

Quality Critical

Comprehensive inspection for automotive, medical, and aerospace applications requiring stringent quality control. Meets advanced traceability and documentation requirements.

Frequently Asked Questions (FAQ)

Contact Us

If you have further enquiries, don’t hesitate to reach out to us and someone will get back to you.