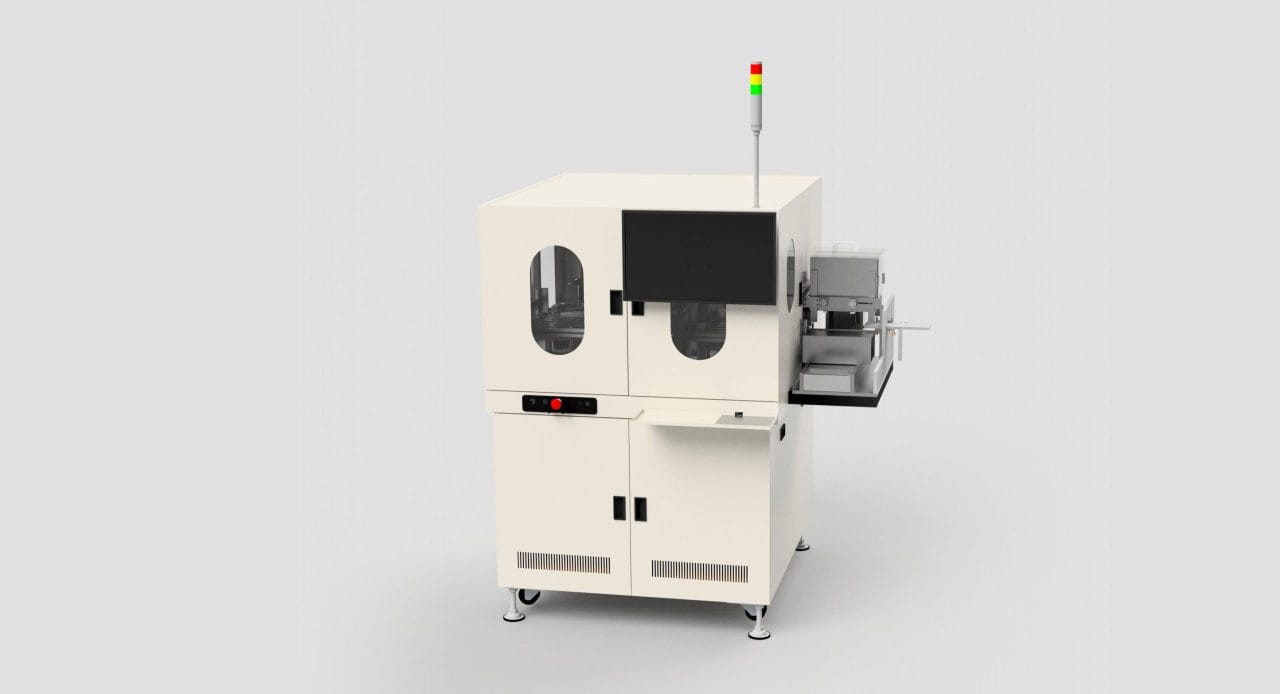

The AMB PM-2800 is a precision-engineered Pick and Place Machine designed for high-speed, high-accuracy transfer of WBG substrates like AMB from incoming trays to sinter trays. Built for semiconductor front-end automation, it combines vision-guided correction, and magazine-based tray handling to support demanding packaging lines. Trusted by industry leaders, it’s engineered for reliability, accuracy, and seamless integration into your factory.

Key Features

Vision-Guided Alignment

Three-stage vision system detects AMB pickup success, corrects XY and theta alignment, and verifies placement in the sinter tray for maximum positioning accuracy and yield.

- Alignment correction in real-time

- Detects pickup, position, and orientation

- Vision check on tray placement

Motorized Z and Theta Pick Up Head

- Programmable Z height

- Programmable Theta Angle

- Auto tray height offset

Full Tray Handling Automation

Supports automatic stacked tray input and magazine unloading for sinter trays, reducing operator workload and allowing uninterrupted operations.

- Incoming tray stacker (14 trays)

- Dual magazine unloading station

- Sinter tray orientation detection

Benefits

Precision Placement with Vision Correction

The integrated multi-stage vision system ensures substrates are picked, aligned, and placed with ±50μm accuracy—ensuring zero-defect placement even with tray or substrate variation.

Enhanced Production Efficiency

The system is designed for fast setup and streamlined operation. Automated handling reduces manual intervention and supports continuous production without sacrificing quality.

- Efficient changeovers between tray sizes

- Minimal operator input required

- Built-in diagnostics for uninterrupted operation

Factory Integration Ready

Equipped with SECS/GEM (optional), recipe management, HMI in English, and diagnostics/alarm system.

Applications

Semiconductor Production

WBG AMB Substrate Transfer

Designed specifically for handling ceramic AMB substrates used in Wide Band Gap (WBG) semiconductor modules. Suitable for front-line automation between shipping trays and sinter process

Designed specifically for handling ceramic AMB substrates used in Wide Band Gap (WBG) semiconductor modules. Suitable for front-line automation between shipping trays and sinter process

Advanced Packaging

Power Module Assembly Lines

Fits into automated lines for power semiconductor packaging, including IGBT and SiC module assembly where substrate precision placement is critical.

Fits into automated lines for power semiconductor packaging, including IGBT and SiC module assembly where substrate precision placement is critical.

Special Components

Automotive & Industrial Semiconductor Manufacturing

Supports high-reliability packaging lines where placement repeatability, traceability, and process stability are mandatory for automotive-grade modules.

Supports high-reliability packaging lines where placement repeatability, traceability, and process stability are mandatory for automotive-grade modules.

Frequently Asked Questions (FAQ)

Contact Us

If you have further enquiries, don’t hesitate to reach out to us and someone will get back to you.