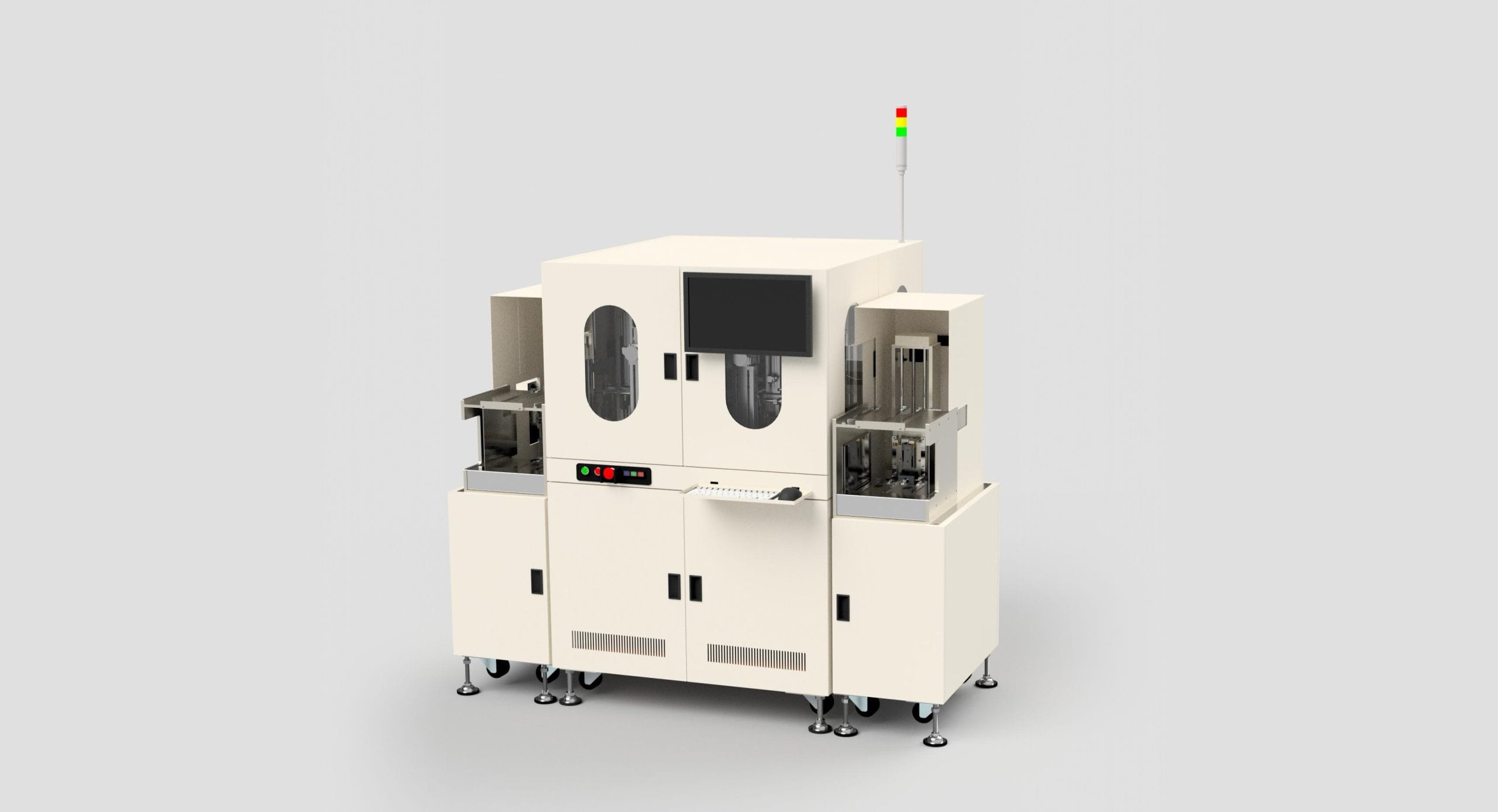

The Die Laser Marking System is built for semiconductor leadframe marking tasks. It integrates laser control, motion handling, and mark verification into one system. Designed to fit into high-volume production lines, it ensures consistent marking results while supporting traceability and handling requirements specific to leadframes.

Key Features

Advanced Laser Control

The system employs precision laser technology with real-time power and focus adjustment, delivering consistent and clear marks. Thermal exposure is carefully managed to protect sensitive surfaces and maintain structural integrity.

- Fine-resolution laser marking

- Adaptive energy and focus tuning

- Stable performance across material types

Intelligent Mark Verification

Built-in optical verification checks every mark for contrast, position, and legibility. Advanced image processing ensures quality compliance while reducing operator dependency.

- Inline inspection for 2D codes, OCR, and custom marks

- Automated defect detection and logging

- Seamless integration with quality systems

Automated Handling System

Engineered for leadframe strip transport, the system ensures smooth and precise movement throughout the marking process. It accommodates a wide variety of leadframe formats with minimal manual adjustment.

- Supports diverse leadframe geometries

- Quick-change mechanism for format transitions

- Accurate alignment with protective clamping features

Benefits

Consistent Marking Quality

Advanced laser modulation and real-time verification enable consistently high-contrast marks that meet industry requirements. Careful energy control prevents surface damage and ensures mark readability.

- Compliant with semiconductor marking standards

- No surface blistering, overburn, or deformation

- Readable by both human and automated systems

Enhanced Production Efficiency

The system is designed for fast setup and streamlined operation. Automated handling reduces manual intervention and supports continuous production without sacrificing quality.

- Efficient changeovers between leadframe types

- Minimal operator input required

- Built-in diagnostics for uninterrupted operation

Complete Traceability

All marking data and verification results are logged automatically, supporting complete component traceability. The system can be connected to upstream and downstream systems for full workflow integration.

- Secure serialization and data stamping

- Marking history available for every component

- Compatibility with MES and ERP systems

Applications

Semiconductor Production

Optimized for leadframe marking, supporting various strip sizes and materials. Ideal for product ID, traceability, and assembly tracking.

- Clear, durable marks on plated or unplated surfaces

- Supports pre- or post-die attach workflows

Advanced Packaging

Accurate marking for high-density packaging such as QFN, LGA, and other leadframe-based designs. Suitable for fine-featured applications without risk to adjacent structures.

- Designed for complex geometries

- Maintains clarity near singulation or bonding areas

Special Components

Adaptable for industries requiring strict compliance such as automotive, medical, and aerospace. Capable of meeting diverse formatting and durability standards.

- Configurable for industry-specific codes and layouts

- Long-lasting, readable marks for critical environments

Frequently Asked Questions (FAQ)

Contact Us

If you have further enquiries, don’t hesitate to reach out to us and someone will get back to you.