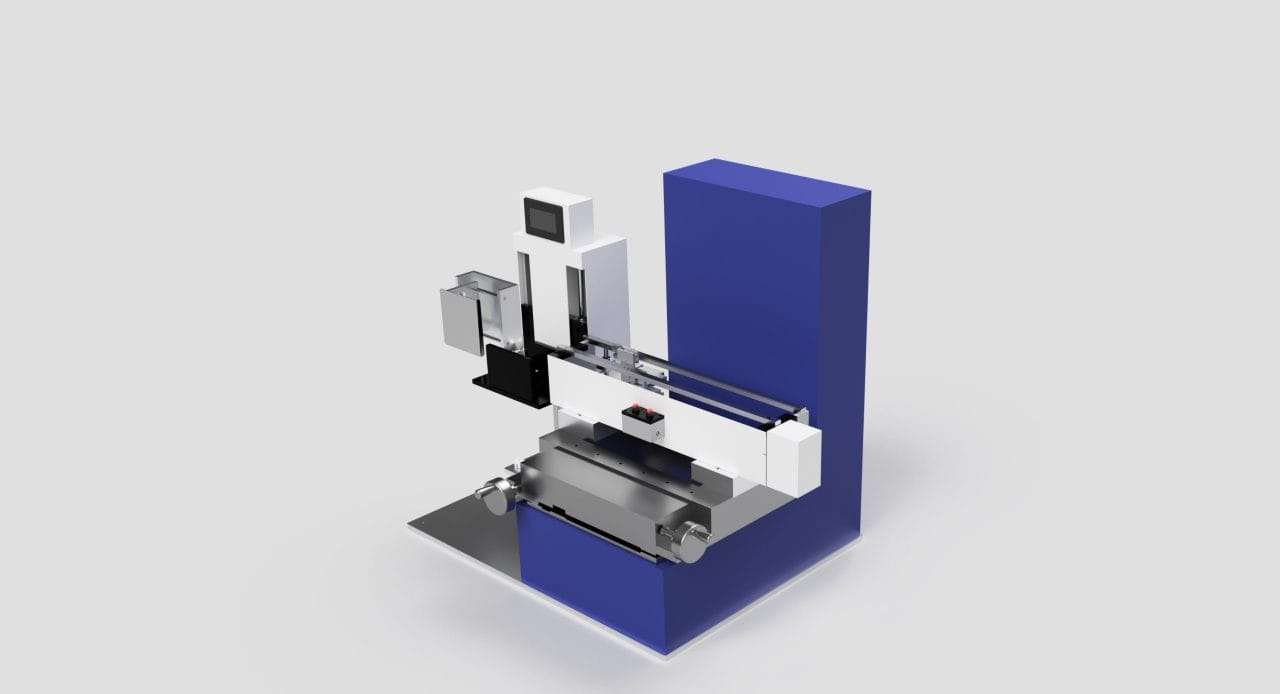

The Die Attach Curing System supports reliable and uniform curing of adhesives used in semiconductor packaging. With programmable temperature profiles and stable thermal control, the system ensures consistent die bonding results. Designed for integration into high-throughput production lines, it balances precision and efficiency for a range of die attach materials.

Key Features

Precision Temperature Control

The system maintains stable and uniform temperature across the curing chamber using multi-zone heating. Real-time adjustments ensure each die receives consistent thermal treatment, minimizing cure variation.

Intelligent Profile Management

Operators can configure detailed temperature profiles including ramp rates, soak durations. This flexibility supports a wide range of die attach materials and process requirements.

Automated Process Monitoring

Built-in sensors continuously monitor temperature and system status during the curing cycle. The system supports logging for process traceability and quality control.

Benefits

Consistent Curing Quality

Accurate temperature control and uniform heat distribution help ensure reliable curing across all units. Real-time monitoring reduces the risk of under- or over-curing, supporting stable bond performance.

Enhanced Production Efficiency

Efficient thermal profiling reduces overall curing time without compromising quality. Automated controls and minimal setup requirements help shorten changeovers and boost line productivity.

Process Flexibility

Customizable profiles allow the system to support different adhesive types, package sizes, and process flows. Easy recipe management and quick adjustments make it suitable for varied production demands.

Applications

Die Attach Processing

Specialized capabilities for various die attach materials including epoxies, films, and sintering materials. Supports different package types and production volumes.

Advanced Packaging

Enhanced thermal processing for advanced package types requiring precise curing control. Supports complex assembly processes and new packaging technologies.

High-Reliability Products

Optimized curing capabilities for automotive, medical, and aerospace applications requiring superior bond quality. Meets stringent reliability requirements.

Frequently Asked Questions (FAQ)

Contact Us

If you have further enquiries, don’t hesitate to reach out to us and someone will get back to you.