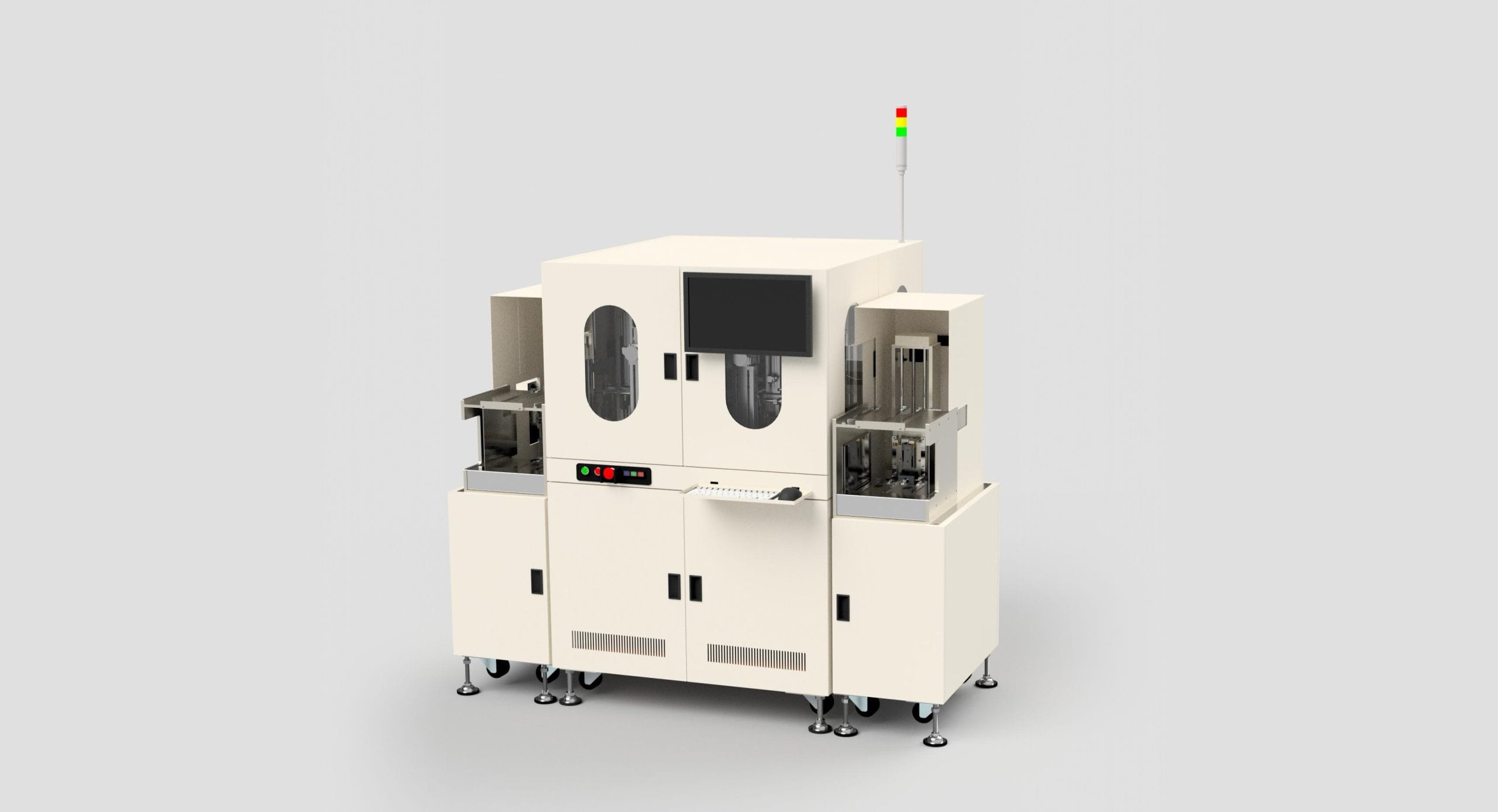

The Automated Leadframe Dispensing System is engineered for high-precision material application in semiconductor manufacturing. It integrates advanced motion control with intelligent dispensing logic to ensure consistent volume accuracy. Designed for high-throughput environments, the system enhances operational efficiency while upholding stringent quality requirements.

Key Features

Consistent Dispensing Performance

The system uses controlled actuation and positioning mechanisms to ensure even material application across leadframes. Its repeatable motion routines help maintain uniform output during production.

Simplified Material Handling

Designed with ease of use in mind, the system supports straightforward loading, material feeding, and dispensing setup. Components are selected for stability and durability under continuous operation.

Operator-Friendly Interface

User-configurable parameters allow quick adjustments for different leadframe types or material requirements. Clear interface and monitoring features help minimize errors and reduce setup time.

Benefits

Reliable Dispensing Accuracy

The system delivers consistent material placement through stable mechanical design and repeatable motion. Proper setup and basic calibration routines ensure accuracy across production batches, helping to reduce material waste.

Improved Production Throughput

Simple automation features such as preset motion paths and tool-free part changes reduce operator intervention. The system is designed for efficient changeovers and minimal downtime between lots.

Quality Consistency

The system maintains stable dispensing results through mechanical repeatability and operator-defined settings. Visual inspection options and recipe-based operation help standardize performance across shifts and operators.

Applications

Die Attach

Supports adhesive dispensing for die attach applications with consistent pattern control. Compatible with a variety of adhesive types and die sizes.

Encapsulation

Suitable for basic blob dispensing of encapsulant materials. Works well in dam pre-fill or targeted fill steps requiring single-point deposits.

Advanced Packaging

Supports dispensing tasks such as underfill initiation or adhesive dots for edge reinforcement. Accommodates small components requiring precise blob placement.

Frequently Asked Questions (FAQ)

Contact Us

If you have further enquiries, don’t hesitate to reach out to us and someone will get back to you.