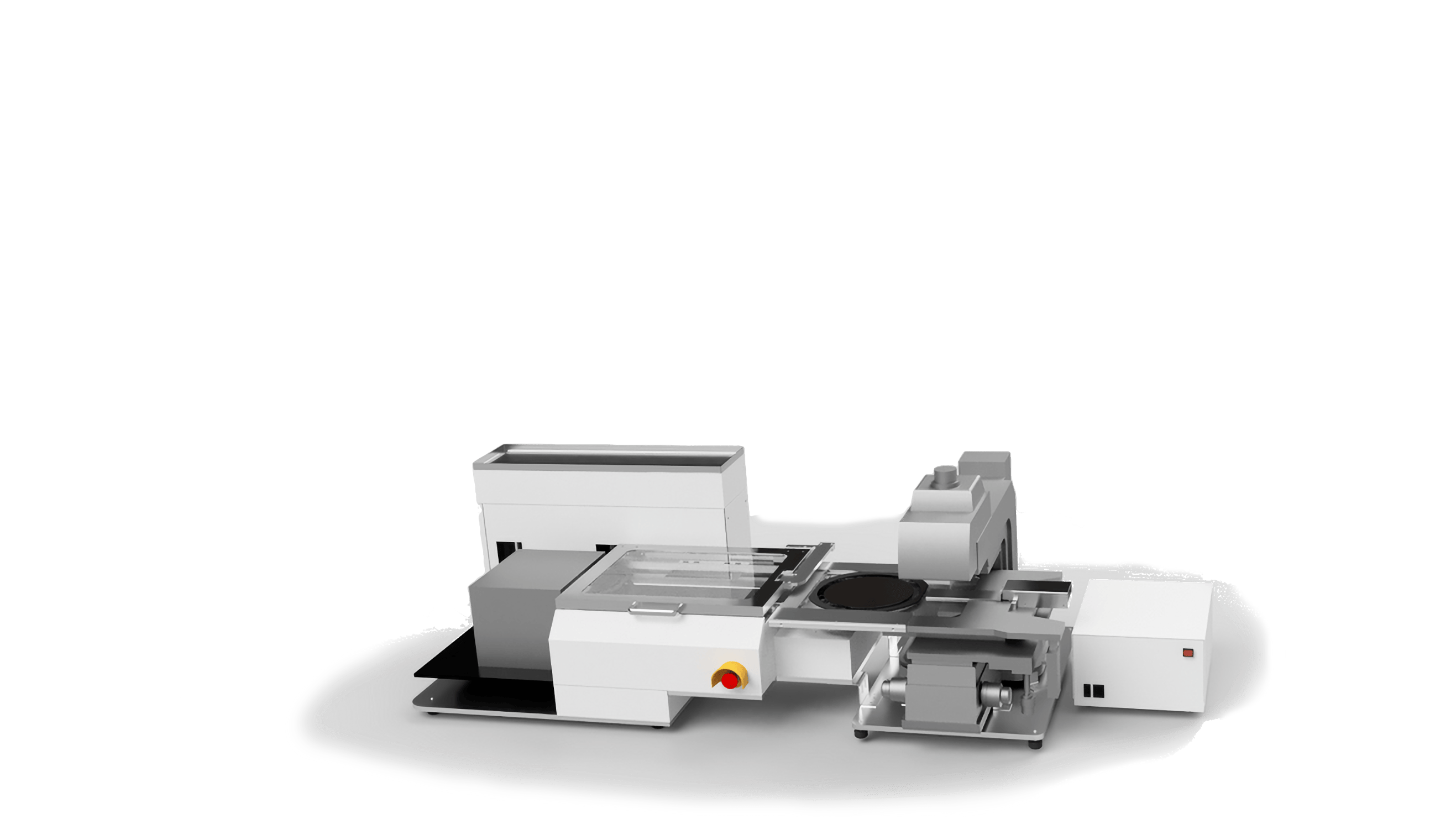

The 3rd Optical Inspection System enables effective inspection at a critical stage of semiconductor manufacturing. Built for ease of use and consistent performance, it allows operators to visually assess components for defects or abnormalities before final processing. The system is designed for inline or offline use, ensuring smooth integration into a variety of production workflows.

Key Features

Visual Surface Inspection

Enables operators to identify visible defects such as surface damage, contamination, or handling issues. High-magnification tools and an ergonomic setup support accurate, fatigue-minimized inspection.

Integrated Strip Mapping

The system includes strip mapping capability, allowing operators to indicate fail positions directly on the inspection interface. This improves traceability and facilitates downstream sorting or binning processes.

Inline-Compatible Design

Designed to integrate into inline production or standalone setups. The system accommodates various carrier formats and supports smooth handling within high-mix, high-throughput environments.

Benefits

Reliable Visual Defect Detection

The system provides a stable and ergonomic platform for operators to identify surface defects, contamination, or mechanical damage. Clear magnification and standardized inspection flow enhance consistency across shifts..

Minimal Disruption to Production

Designed for high-throughput environments, the system supports smooth inline or offline integration. Inspection is fast and efficient, minimizing impact on overall cycle time without compromising quality..

Integrated Strip Mapping for Traceability

Built-in strip mapping functionality allows operators to mark fail positions accurately, enabling effective downstream sorting, rework, or binning. This improves traceability and supports quality documentation.

Applications

General Inspection

Suited for visual inspection of semiconductor components to identify surface defects, discoloration, handling marks, and contamination. Commonly used in post-assembly or pre-packaging quality checks.

Quality Gate in Manual Flow

Deployed as a quality checkpoint in manual or semi-automated production lines. Enables operators to visually screen units before downstream processing, with strip mapping to flag defective areas for sorting or rework.

High-Volume Manufacturing

Ideal for environments handling a variety of package types or frequent product changeovers. The flexible inspection process accommodates different leadframe or strip formats with minimal setup times.

Frequently Asked Questions (FAQ)

Contact Us

If you have further enquiries, don’t hesitate to reach out to us and someone will get back to you.